As a kind of worldwide popular snack, fried potato chips producing is certainly in large demand. A Jas enterprise offers several potato chips production lines which contains batch type potato chips line, semi automatic potato chips line and fully automatic potato chips lines.

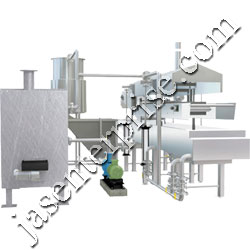

Semi automatic potato chips processing system includes following equipment

Semi automatic potato/banana chips line products made by the line are

The equipment peels potatoes with minimum peel loss; water is sprayed on the product for better peeling. Peel waste is carried away with this water and flows to drain.

Potato peelers are made from heavy duty stainless steel 304 fabricated body. Stainless steel 304 peeling chamber coated with abrasive emery, which peels the potatoes. Stainless steel peeling chamber’s bottom plate is drive with help of suitable 4 pole totally enclosed fan cooled single or three phase squirrel cage motor as per is: 325 or 996{electricity (special power can be accommodated): 110/220/380/415 volts, 50/60 Hz, 1 or 3 phase}

Potato slicer, which can produce plain, ruffles and potato sticks. There is a provision to adjust slice thickness. Continuous water supply is given to equipment to avoid deposition of broken pieces in die.

Automatic potato slicer is made for stainless steel 304 grade potato chips making machines that are in wide demand in the global marketplace. Commercial potato chips machine is made from heavy duty stainless steel fabricated body. Adjustable stainless steel blades are fitted on aluminium die. Chips slicing die is rotated by suitable electric motor. Base of chips machine is made from mild steel angle and covered with stainless steel sheet. Stainless steel easily detachable hopper is supplied with these potato slicer.

The equipment removes excess surface water from the slices and separates them prior to frying. Hydro is made of stainless steel 304 with proven technology. Washed potato / banana poured into the drum of hydro extractor from top, the inner stainless steel perforated round holes screen removable drum rotates at the high speed. Water will remove from potato / banana by hydro extractor. Detach the drum and remove semi dry material from drum as per our standard supply. The hydro extractor drum rotated by suitable electric motor.

After removing water from hydro the slices are feed manually into the hopper. The hopper is designed in such a way that the feeding take place through a metered system, the speed of feeding can be controlled by a variable frequency drive. All stainless steel (AISI 304) construction except standard components viz. Drives motor and bearings/ fittings et cetera

Specification of hopper with metered feeder:

Drive motor: variable speed, 0.5 HP 3 phase

Dimensions: - 4 x 2.5 x 5 ft

The equipment receives slices from the metered feeder and directly feed to the fryer, the shaking movement removes small pieces and particles will be removed and collected in a tray. The speed of shaking can be controlled by a variable frequency drive. All stainless steel (AISI 304) construction except standard components viz. drives motor and bearings/ fittings et cetera The shaker is supplied with suitable geared motor 0.5 HP 3 phase.

Advance Features of Continuous frying system with heat exchanger

Lightweight ceramic fibre insulation keeps casing temperatures low and does not deteriorate from age or thermal stress. Low residual heat capacity enhances temperature control and eliminates overheating of oil during unscheduled shutdowns.

Completely self-draining, our all-welded stainless steel tube bundles stay clean of particle accumulations. Normal thermal expansion produces no stressing or buckling of the tubes, assuring years of reliable, trouble-free operation.

For cooling of oil a shell and tube heat exchanger will be provided along with fryer for better oil management.

The fryer comes with pneumatic auto lifting arrangement of conveying system for easy cleaning and maintenance.

Complete material of construction will be stainless steel 304.

The electrical control panel houses all the starters, temperature controllers and variable frequency drives for operation of equipment.

Supply voltage: - 415 volts, 50 Hz, 4 wire